What is the sleeve for the CYBI active traction arm prosthesis made of

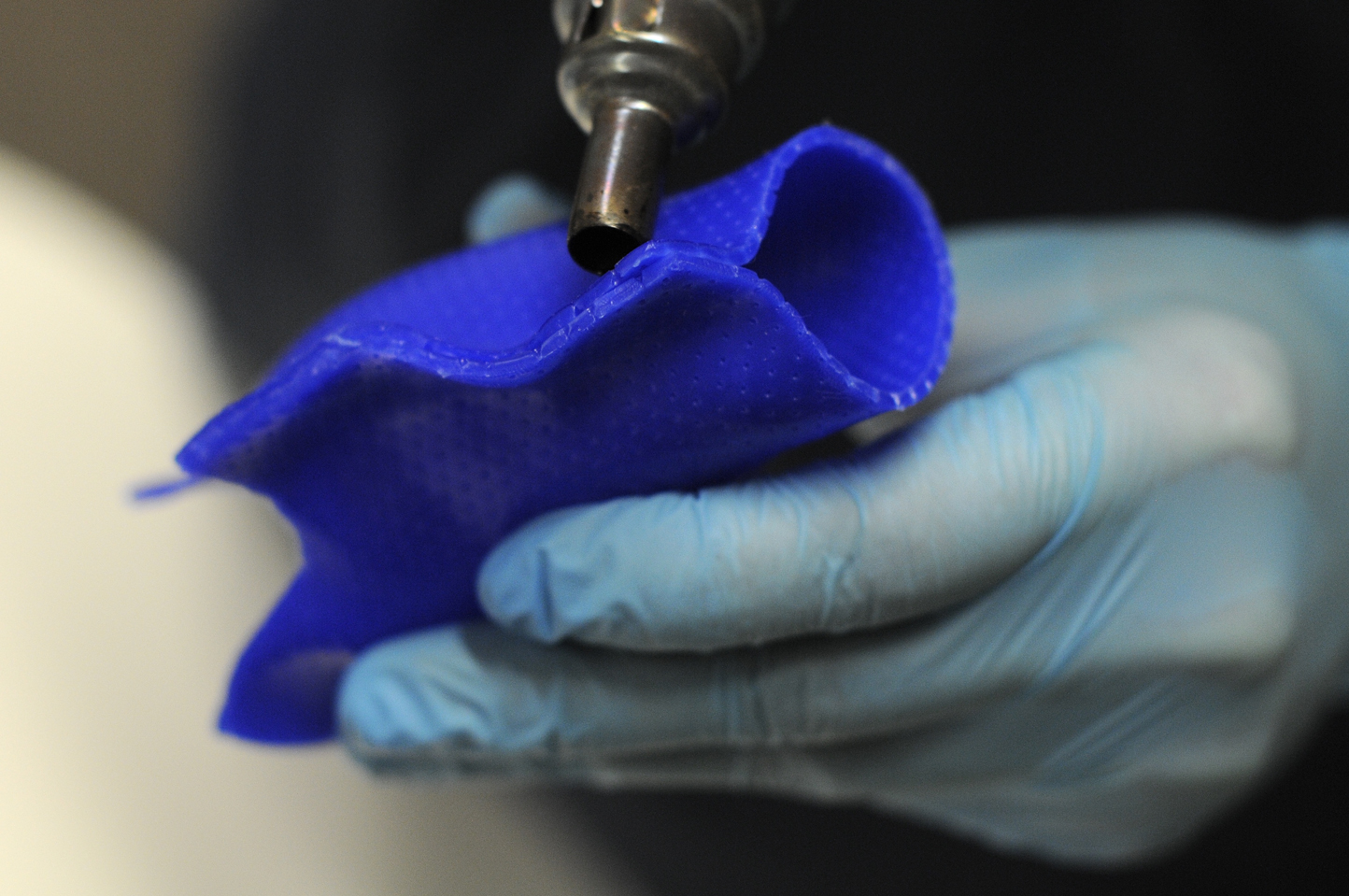

Prosthetists create the sleeve from a mold or directly on the arm using a special material called thermoplastic orfit. It has micro-perforations, which help improve heat dissipation from the residual limb.

In its normal state, this is a hard material. To shape the sleeve, it is immersed in hot water for a period of time, making it pliable, and then it is molded into the socket. Orfit is hypoallergenic, making it suitable for most people.

How to determine if the sleeve for an active traction prosthesis of the hand or forearm is made correctly

Our specialists shared some criteria that can help determine if the prosthesis is made correctly and can perform its functions:

It is important that the sleeve visually has no rough edges or signs of poor workmanship. If there are fastening elements inside or outside the sleeve, they should not protrude. The sleeve must not damage the skin.

When using the device for 10 minutes or more, there should not be significant abrasions or pain sensations.

Due to the nature of the injury, the socket may fit tightly onto the arm. However, it should not be excessively tight: if lubricant does not ease the application of the sleeve, then it needs to be adjusted.

In most cases, the sleeve feels more comfortable after an adjustment period. If you or your child feel uncomfortable, our specialists are always available.